How to Make Good Concrete PE Insulated Tarps?

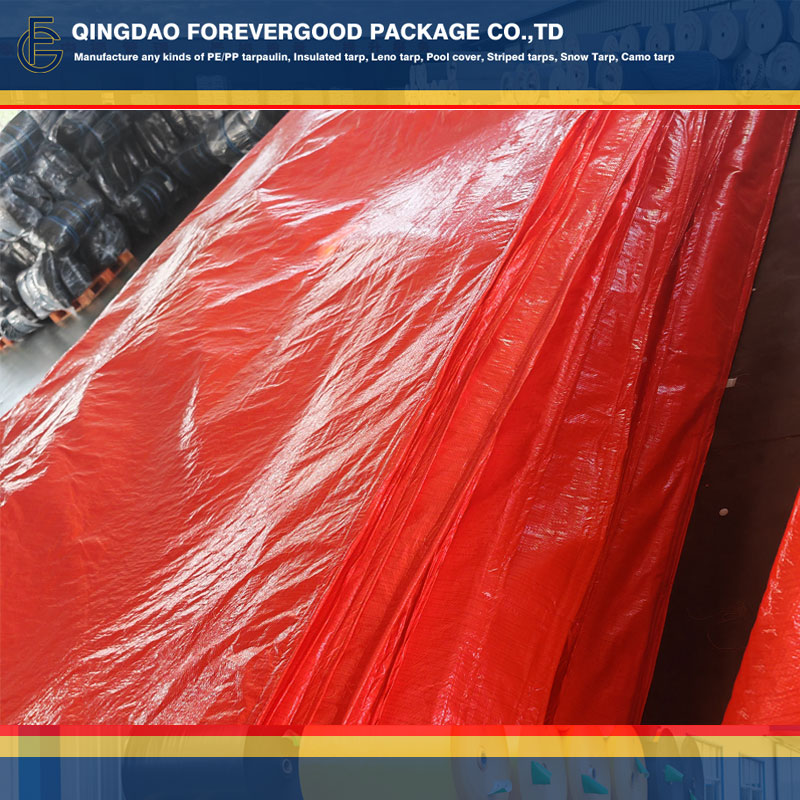

Before starting for making the concrete PE insulated tarps, we shall clear the clients's need first. Choose the right and available GSM tarps and most suitale colors. The standard gsm of the outside of the PE tarps are prefers the 50gsm to 85gsm, if clients final used are outside for long time use such as Farming or Salt use. It's better to use at least 100gsm to 150gsm outside PE materials. It will be much stronger enough and it could take very long time use life. Normally, the PE materials colors are Orange, White, Blue, Black, Silver, Grey and Yellow and others. However, orange, white, silver, black are the most porpular colors choices.

The Concrete insulated tarps are combining two outside PE tarps materials, the inner sides are EPE foams. And the inner sides could be used 1 layer, 2 layers, 3 layers and 4 layers. Currently the most thickness are 16mm, that means max thickness we can make are 4layers *4mm.

How to sew or stitch the two PE tarps and EPE foams? There are two ways to stitch, double stitching are the normaly way for stitch the four edges, and some will use the single stitch but it's the passed ways. We never use it again.

Some clients will use the sewing tags on the long sides. And some clients will not use. Also some clients will ask the tarps to print the logos.

Different package have different loading quantity, normaly clients will use the bulk package to load as more as it could be in a 40HQ container. Some clients will use Pallet package, this way could reduce the loading quantity in a 40HQ containers, but it's easy for load and unload.